Our state-of-the art cutting capabilities ensure that each piece of glass is processed to the highest standard in accuracy and quality of cut.

In addition to our high quality of cutting standards we also have the ability to produce a variety of different shapes. The NWI Shape Catalogue gives an overview of just how many shapes we are able to fabricate.

Tempered safety glass provides the perfect solution for both general and safety glazing projects including sliding doors, building entrances, and interior partitions where superior strength and safety are required.

NWI’s tempered glass can provide up to triple the resistance to thermal shock and four times the load resistance compared to standard, annealed, untempered glass.

Our process of creating tempered glass consists of two steps: first, the glass is heated to a very high temperature and then it is immediately cooled. This process creates a piece of quality glass that shatters safely into small pieces upon impact.

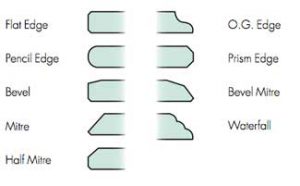

Our ovens are capable of handling glass which measures up to 96″ x 192″. In addition, our furnaces are supported by fabrication equipment for handling holes, notches, cutouts, and edge work.